Hot state member checks

Posted on 15th February 2022 at 20:31

We have generated hot state versions of all our in house calculations for light gauge steel negating the need for testing.

We are pleased to be able to share that we have generated the ability to calculate all members under hot state conditions in our in house light gauge steel calculations from now onward. These calculations are to both British Standards and Euro Codes to negate the need for testing and the limitations of testing.

This means that as we design your roof, floor and walls in light gauge steel as well as offering the usual 'cold state' calculations we can offer calculations to confirm if the members can carry the required loads under fire conditions. This applies no matter how high the loads are unlike physical testing which has to have limitations based on the ability of the test rigs.

These calculations are to EN1993-1-2 and BS 5950-8 to allow the calculation of member capacities at elevated temperatures and reduced load factors as in the fire condition. This is a calculation, not testing or extrapolation from testing, but a pure and simple calculation identical to the ones carried out in the ‘cold state’, i.e. to BS 5950-5 and EN 1993-1-3.

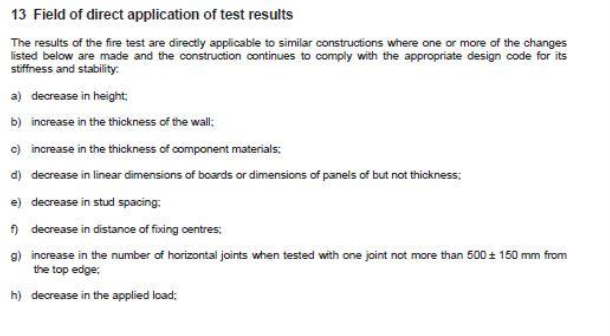

This calculation, we believe, is required as EN1365-1, Clause 13 lists changes that can be made to the as-built / designed structure without invalidating the test report and data and this includes as point ‘h’, that load applied can only be decreased.

This is an issue for two reasons. The more load applied, the quicker a member will fail. For example, if loaded to 99% of its cold state capacity, then heated up in the event of a fire it will, not unreasonably, not take too long for the effect to be felt and the member sufficiently softened to reduce the strength to the point of failure.

Secondly, the test rigs have a limited amount that they can apply to the tested panel, whereas studs can carry more than the test rigs can apply, so there is a disparity. Calculations are not limited in this way.

The calculation offered does not offer a ‘fire rating’, instead relies on data from board manufacturers to provide what is effectively the insulation value. If board manufactures do not wish to supply this data, then Light Gauge Steel manufacturers, Trade Bodies, Special Interest Groups, etc. can test the boards themselves and then use that data to calculate fire resistance times.

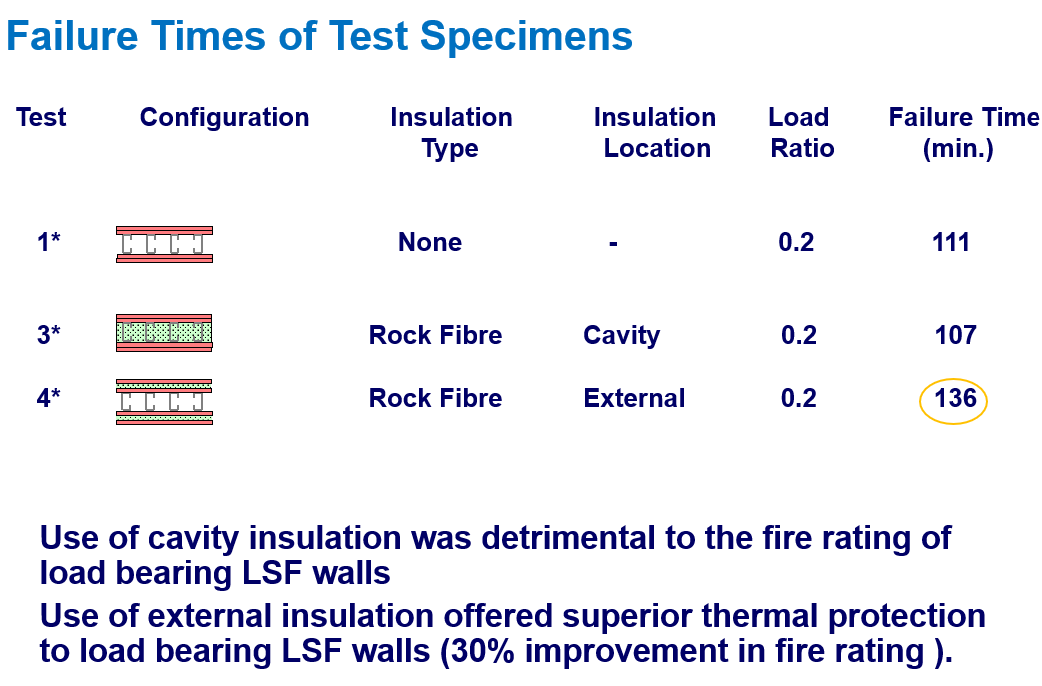

These calculations come from five years of research and development into pro rating test results and research with various Academic and Professional Institutions, but the inspiration for using existing calculations and methodologies came from conversation with staff at NHBC and have been discussed with staff at LABC in the UK. As part of this period of research we have discovered that putting insulation between studs is great for acoustic performance but has a negative impact on the fire case as it traps the heat between the flanges and thus the stud is heated for longer which ultimately reduces the fire rating.

The calculation is based on the stud reaching a pre-determined temperature, 550oC in our current examples, and the yield strength being reduced in accordance with the tables in the BS 5950-8 and EN 1993-1-2. This temperature can be set by the individual LGS manufacturer and the section properties re calculated based on their preferred temperature – lower temperatures mean higher strength, but potentially lower fire rating or more boards.

Share this post: